Products

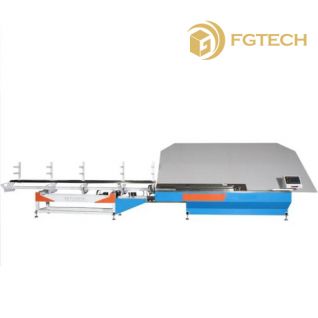

CNC Glass Engraving Machine-Flat Glass Printing Engraving Machine

FHD-EM3019 CNC glass groove machine is numerically controlled and used to engrave straight line and curve on the surface of flat glass of certain size, it can process 1~20 pcs glass with same size and same drawing.

Basic Info.

FHD-EM3019 Glass grooving machine technical configuration

FHD-EM3019 CNC glass groove machine is numerically controlled and used to engrave straight line and curve on the surface of flat glass of certain size, it can process 1~20 pcs glass with same size and same drawing.

The procedure is: design any kind of engraving picture as you like in the computer, enter related engraving information, change these information into NC code, NC code will be changed to G code by numerical control system. The numerical control unit will use these code to coordinate and control the spindle movement along X,Y,Z,C axis and main spindle rotating, in this way the desired engraving picture will be made out. The shininess of straight or curve line will be almost the same as glass itself after being polished. Change the tools by automatic.

Main technical data

Max. Processing glass size:3000×1900mm

Processing thickness:4~40 mm

Grooving max. width: 20mm

Axis stroke(X,Y,Z): 3000, 1900, 200mm

Max. Speed for X,Y,Z: 40/30/5m/min

Max. speed for spindle:3500rpm

Main spindle:5.5kw

Max. Diameter for the wheel:φ170

Tool rack:10

Total power:22kw

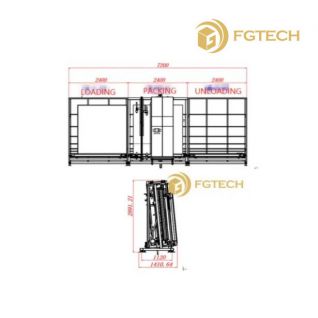

Overall size(X,Y,Z):5700×3000×2200mm

Gross weight:6500kg

Finished tolerance:±0.150mm

Main configuration

Ball screw:Taiwan brand screw

Straight line guide rail:HIWIN

Timing belt:Megadyne

Control system:HNC China.

Servo system:HNC China

Main spindle inverter:Inovance

Main spindle motor:China

Low voltage electrical equipment:Schneider

Pneumatic component:AirTac

Product Characteristic

CNC system uses PC + motion controller control mode, a high-performance, flexible configuration, easy to use, and high reliability.

CNC system can use English operating interface, fault diagnosis and alarm processing path graphic display, simple operation, easy to learn and use.

International standard G-code programming process is compatible with a variety of popular CAD / CAM automatic programming system, with linear and circular interpolation, cutter compensation function.

Pitch and backlash compensation.

Y-axis gantry synchronization control function, synchronization accuracy of feedback regulation and control, to ensure the accuracy of the real-axis synchronized motion.

Modular PLC digital and analog I / O interfaces, expansion convenient, easy system upgrades.

CNC system and CAM software run in the same PC. User can use CAM software to draws the program and generate the processing code, then send the NC code directly to CNC systems, streamline operations, saving processing time.

CAM software comes with simulation capabilities, product processing before the actual process trajectory simulation run checks zero error processing.

CAM software support .dxf file import.

CNC system software and CAM software runs under Win-XP or Win732bits system

Polish: introduction of the grinding and polishing of setting compensation function in the system to meet the sustained and stable polishing effect.

Main spindle: Maximum speed of up to 3,500 rev / min to ensure efficient grinding.

Servo drive system: use digital servo drive and absolute encoder servo drive motor. CNC system and Servo drive use NCUC bus communication to ensure the control signal transmission speed and strong anti-interference ability. Accurate control of X, Y, Z of the feed rate and C-axis rotation.

Automatic Tool Changer: 10 tools stored in the push-magazine, making the whole process from rough grind, fine grind and polishing at once.

Multi-Position: multi-position chucking glass, to ensure efficiency.

Precision ball screw and guide rail: ball screw and guide provided by the well-known Company. Automatic centralized oil lubrication. Combined with effective waterproof, dustproof structure to ensure high-precision machining, and maximize ball screw and guide life.

Machine picture

Processed Glass

5+5 tools

Servo Drive

High precision ball screw and guide rail

Automatic lubrication system

Rough grooving

Automatic compensation for polishing

Polishing wheel from φ170 to φ110

Auto/Manual

CNC system,

stable and reliable performance, simple operation

Same as WINDOWS system, CAD/CAM design and programming software, which can be designed and Edit graphics and automatically generate the function of the process.Can directly import the DXF, file format

Servo System

Part list

| No | Description and specification | Qty | Remark |

| S1/10 | internal hexagonal wrench S4,5,6,8,10 | Each 1 | Carton package |

| stud dead spanner8-10,12-14,17-19 | Each 1 | ||

| Double plum wrench 17-19 | 1 | ||

| adjustable spanner 450X55 | 1 | ||

| Screwdriver for cross-recessed head screws 125X6 | 1 | ||

| Air pipe φ6Xφ8 | 20m | ||

| Thread seal tape | 2 | ||

| Diamond wheel V6 | 1 | ||

| Diamond wheel V8 | 1 | ||

| Polishing wheel V6 | 5 | ||

| Polishing wheel V8 | 5 | ||

| Electrical diagram | 1 | ||

| Operation and maintenance manual | 1 | ||

| CAD/CAM operation manual | 1 | ||

| S2/10 | Main body | 1 | Film package |

| S3/10 | Cabinet | 1 | Film package |

| S4/10 | Vacuum pump | 1 | Film package |

| S5/10 | Vacuum pump tank | 1 | Film package |

| Steel wire rubber hose Φ16XΦ10 | 1m | Film package | |

| Air pipe Φ16xΦ13 | 1m | ||

| S6/10 | water tank | 2 | Film package |

| Water pump 750W | 1 | Film package | |

| Tools module | 1 set | ||

| Adjusting washer | 100 | ||

| Foot pad | 6 |