Products

Automatic Winding Equipment

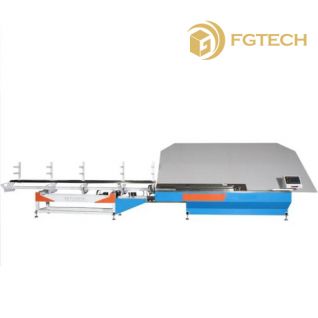

The new "high speed" type 1000 stretch film unit (cling film unit).

Our company machines all comprehensive through the CE quality certification and ISO quality system authentication.

Basic Info.

The new "high speed" type 1000 stretch film unit (cling film unit).

Our company machines all comprehensive through

the CE quality certification and ISO quality system authentication.

Name |

Model | QTY | Unit |

| 2/3 Layers Co-Extrusion Cast Stretch Film Unit | CL-55/70A | 1 | set |

1.Machine specification

1,Thickness adjustment scope:10µm-50µm;

2,Equality percent of thickness:≤±5%;

3,Width of effective film:1000mm or 2*500mm(max) ;

4,Cast Stretch Film structure:A/B or A/B/A Co-extruded;

5,The fit material:LLDPE,LDPE, MLLDPE;

6,Extrusion Capacity(max):135kg/h;

7,Installation dimension(L*W*H): 7*3*3.6m;

8,Weight: 8T.

2.Main technical parameter:

First,Produce system

(1),CL-70-30 Middle Layer Single Screw Extrusion (Layer B)

- Screw is adopted special mixing function and high plasticizing capacity design, to ensure good plasticizing, uniformity color and luster;

- Alloyed Screw rod diameter:Φ70mm;

- The L/D ratio 30:1;

- Material: 38CRMOALA special high quality alloy steel, surface precision nitriding treatment;

- Gear box is adopted extruder dedicated reducer, with Italian super precision design and endurable and wear resisting;

- Main motor "American KDS Brand" 22KW one set;

- Main DANFOSS inverter 22KW one set ;

- 900CC Automatic loader one set.

(2),CL-55-30 Viscous Layer Single Screw Extrusion (Layer A)

- Screw is adopted special mixing function and high plasticizing capacity design,to ensure good plasticizing, uniformity color and luster;

- Alloyed Screw rod diameter:Φ55mm;

- The L/D ratio 30:1;

- Material: 38CRMOALA special high quality alloy steel, surface precision nitriding treatment;

- Gear box is adopted extruder dedicated reducer, with Italian super precision design and endurable and wear resisting;

- Main motor "American KDS Brand" 15KW one set;

- Main DANFOSS inverter 15KW one set ;

- 900CC Automatic loader one set.

Second,Die head & divider system

- The adjusting die head:manual;

- T-Die Brand: CHANGLONG;

- Material: superior special steel 718 h;

- Die head width:1 250mm;

- Heating Type: Stainless steel high temperature resistance electric heating tube;

- Temperature control: automatic temperature control with a total of 9 zones by using smart

- The gap of die head:0.8mm;

- Oscillating Unit

Specifications of guide roller: aluminum Φ 80x1250mm 8 pieces

Oscillating power: 100W gear motor

Oscillating range: 100mm

- The construction of divider: A/B or A/B/A two sets;

- Oil pressure filter changer two sets;

- Electric side film locker device one set;

- Robot Hands one set.

Third,The assistant cooling part

- The diameter of cooling roller(the film cooled by the first roller) is Φ500mm,

the length is 1250mm. many inner helical ways make the temperature of the roller equally;

- The diameter of cooling roller(the film cooled by the second roller) is Φ500mm,

the length is 1250mm.many inner helical ways make the temperature of the roller equally;

- The decelerate TAIWAN GPG motor of cooling roller:the power is 3.7KW with DANFOSS inverter 3.7KW one set.

Fourth,Automatic rubbing reeling roll system

- Winding Model: rubbing reeling roll system;

- Winding Roller size: φ370mm *2;

- Paper core size:insideφ76*outsideφ96mm;

- Air Shaft two PCS (Taiwan pneumatic core shaft with Japan's air rubber tube );

- Width of film: 1 000mm(max), film size cut on line;

- The motor with material decelerate 2.2KW one set(Taiwan GPG);

- Take-over DANFOSS inverter 2.2KW one set.

Fifth,Edge recycling system