Products

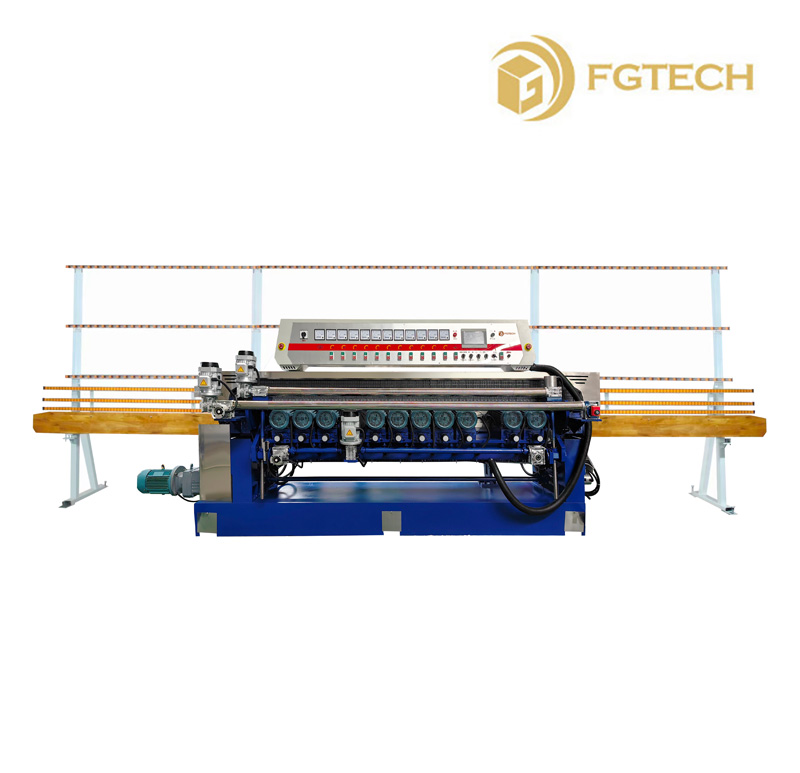

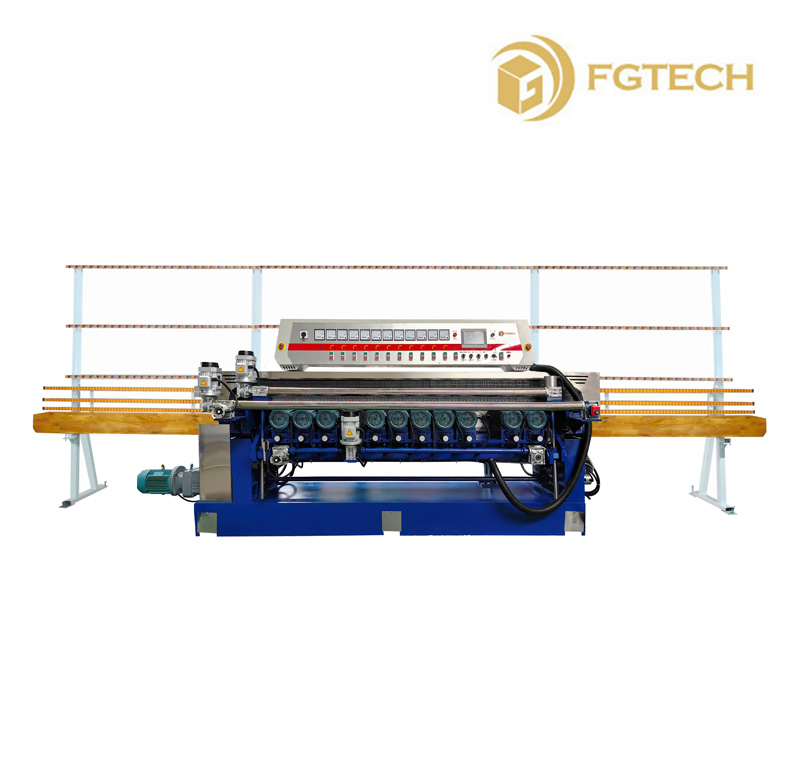

Glass Straight Beveling Machine-Beveling Processing Equipment-Glass Processing Machinery

This machine is specially designed for making bevel on small glass (30x30mm) and big glass(3mx3m), it can also make 45 degree miter edge.

Basic Info.

Description of the Equipment

1. Glass straight- line beveling machine, Model No.: FGE-VB-ZC471D

This machine is specially designed for making bevel on small glass (30x30mm) and big glass(3mx3m), it can also make 45 degree miter edge.

Technical Specification:

Spindles: 12 heads.

Speed: 0.8m-4m/min

Max. bevel width: 50mm

Min. glass size: 30mm(width)X30mm

Glass thickness: 3mm-19mm

Bevel angle: 0°-45°

Total power: 30 KW (380V 50Hz)

Total dimension: 10.2mX1.2mX2.6m

Weight: 6500Kg

Description:

1.Back conveyor track height adjustment.

This machine is designed to make bevel on small glass and big glass. The back conveyor track can be moved up and down according to glass size. For small glass size, the back conveyor track can be moved upward. For big glass size, the back conveyor track can be moved downward

2.Control

This machine adopt PLC control and operator interface. The Screen can show glass thickness, bevel angle, bevel width and back track height. The machine can be set automatically through computer, or can step by step setting through the switch on control panel. Automatic setting

Automatic setting setting manually through switch.

setting manually through switch.

Are made of cast iron to ensure stability and solidity.

4.Conveyor:

Front and back Conveyors use ball bearing conveyor, the drive gear directly drive the roller of each pad. This system is very strong and suitable for small glass (30mmx30mm) and heavy glass(4mx4m) processing.

Back conveyor has cleaning brush, which ,maintain a clean surface and guarantee working result.

5.Motor

Use high precision low vibration ABB motor, specially for beveling machine.

6.Loading/offloading conveyor

adopt timing belt.

7.Front rail movement:

Motorized, it can move in parallel to adapt to different glass thickness. There is a mechanical thickness readout to show conveyor opening.

8.Glass support frame

Use aluminum bar with blue plastic roller.

9.Lubrication:

The machine equipped a automatic lubrication pump, which lubricate the front and back conveyor.

All the sliding surfaces (including front conveyor movement, grinding beam moving section, motor plates) are lubricated by oil system. The well designed oil lubrication system make sure machine's life time and long-time smooth running.

through frequency inverter system. The inverter use Mitsubishi.

11.Amperometer meter:

check the wheel assportion.

12.Water system

Water is circulated in the machine and stainless water tank. Wheel tank outlets connect with one stainless drain pipe which is very easy for installation. The square water tube for water inlet is connected with each wheel nozzle.

13.Felt wheel use pneumatic system.

Configuration of grinding wheels:

| Wheel pos. | Type of wheel | Motor power | control |

| No.1 | Diamond wheel 150mmx22mm | 2.2kw | Mechanical |

| No. 2 | Diamond wheel 150mmx22mm | 2.2kw | Mechanical |

| No.3 | Diamond wheel 150mmx22mm | Mechanical | |

| No.4 | Diamond wheel (peripheral) 150mmx22mm | 2.2kw | Mechanical |

| No.5 | Resin wheel 150mmx22mm | 2.2kw | Mechanical |

| No.6 | Resin wheel 150mmx22mm | 2.2kw | Mechanical |

| No. 7 | Resin wheel 150mmx22mm | 2.2kw | Mechanical |

| No.8 | Resin wheel 150mmx22mm | 2.2kw | Mechanical |

| No.9 | Felt wheel wheel 150mmx105mm | 1.5kw | pneumatic |

| No.10 | Felt wheel wheel 150mmx105mm | 1.5kw | pneumatic |

| No.11 | Felt wheel wheel 150mmx105mm | 1.5kw | pneumatic |

| No.12 | Felt wheel wheel 150mmx105mm | 1.5kw | pneumatic |

Spare parts:

| Motor 2.2KW-2 | 1 |

| Electronic parts (ZHNT) | |

| Two-way switch with lamp | 2 |

| Ampere meter | 2 |

| Two polar knob | 1 |

| AC contactor | 2 |

| AC contactor with auxiliary contactor | 2 |

| Heat relay | 2 |

| Fuse | 2 |