Products

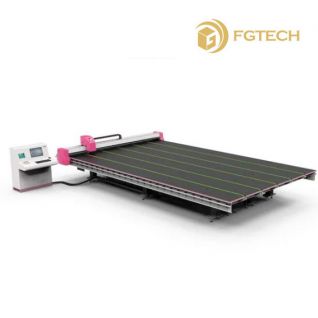

Full-automatic Laminated Glass Cutting Machine

This machine is a new generation for cutting laminated glass automatically. It has the characteristics of simple operation, high adaptability and high cutting precision.

一:(Structure of machine)

Frame was made with international square steel tube and box iron by welding.The key position had been annealing treatment and gantry milling. So the frame has high stability and strength.

Two-part construction to assemble the machine. The first section is the suction cup automatically turning over loading, equipped with belt transmission function. The second paragraph contains the upper and lower knife cutting system, breaking system ,cutting film system, heating system and bidirectional positioning system.

二:(Machine Parameters)

1. Size of machine: 7850*5350*1455mm

Package size:11900*2290*1500mm(One 40 HQ)

2.Weight:about 4500KG

3.Processing range of glass size:400*400mm --- 4200*2800mm

4.Processing range of glass thickness:3+X+3mm---10+X+10mm

5.Cutting speed: 1-2 times/minute

6.Film type: PVB/EVA

7.Temperature and time of heating: Adjust by operator

8.Moving speed of cutter : 0---40 m/min

9.Pressure of pushing and breaking: Adjust by operator

10.Standard Input Voltage :380V/50HZ(Customizable)

11.Maximum power:40.5Kw

三 :(Machine configuration)

1. Motor:Delta SERVO MOTOR

2. Gear reduction motor: Anhui Yonghua

3. Drive: Delta

4. Plc and touch screen: Delta

5. Electrical elements: CHINT

6. Program: Self-Design

7. Heating tube: HONESOM (Gold Coating)

8. Timing belts and wheels: Guangdong Fujiada

9. Air cylinder and knife: Air-Tac

10. Knife wheels: German Bohle

11. Draught fan: Anhui Yinniu

12.Transmission shaft: Zhejiang

13.Table:Composite fibre board

14.Felt: Imported industrial wool felt

15.Proportional control valve: SMC from Japan

16.Frame:Steel pipe welding

17.Sheet metal cover: Spraying plastics(White)

四:(Technical process)

From the HMI setting cutting width, length, pressure and other system parameters -- The manual or lifting tool places the glass on the material rack - After manual start processing ,the suction cup will automatically turn the material over - The belt will transfer the glass to the cutting machine station or wait -- The glass is automatically transmitted and positioned according to the input cutting size (Here with X-Y axis mechanical positioning) -- The cutting head is at zero point -- Pneumatic lower tool, upper and lower tool wheel cutting (Automatic oil injection system can be selected here) -- After cutting, lift the knife -- The upper press wheel starts pressing, lower surface glass breaks off -- The lower press wheel pushes up the glass, upper surface glass breaks off -- The heating tubes starts heating -- The vacuum suction cup adsorbs the glass on both sides of the tangent line and open the slit and start the film cutting (Or select the automatic alcohol spraying function)--The cutting action is complete, and the glass is transferred to the tangent position of the next cutting section(If the cutting direction needs to be adjusted, the rotation action needs to be completed manually with the air floating function)--The overall cutting action is completed--The finished product is transferred to the end of the machine, and the finished glass is unloaded manually or with a suction cup tool.

五:(Advantages)

1.Can automatically load and set the cutting length and width, labor saving;

2. Servo control system is adopted to ensure stable performance, high-precision and efficient;

3.High-quality heating tubes are applied to save film cutting time, and automatic injection of alcohol to melt the film is also available for customers to choose from.

六、(Reference picture)